Contents

10 OSHA Flat Roof Safety Requirements and Best Practices

Your roof is one of the most dangerous locations in your building. According to the most recent data from the US Bureau of Labor Statistics, there were 700 fatalities in 2022 caused by falls to a lower level. Falls were the second highest cause of all work-related fatalities, up 1.8% from the prior year.

Your commercial roof is frequently accessed by HVAC technicians, inspectors, elevator mechanics, roofers, employees and other maintenance personnel. A roofing fall protection plan that follows OSHA requirements, combined with general roof safety best practices, is vital to avoid injuries and fatalities.

How to Improve Flat Roof Safety

Here are ten recommendations to help ensure maximum roof safety at your facilities. They are not difficult to follow, and the outcomes can be lifesaving.

1. Install Guardrails Around Sides and Edges

We recommend installing OSHA-compliant guardrails in common work or walking areas. OSHA 1926.501 requires this fall protection, stating: Each employee on a walking/working surface (horizontal and vertical surface) with an unprotected side or edge which is 6 feet (1.8 m) or more above a lower level shall be protected from falling by the use of guardrail systems, safety net systems, or personal fall arrest systems.

To meet OSHA requirements, the top rails must have a smooth finish and be at least 42” from the walking surface, with a mid-rail, balusters or other protection between the surface and the top rail. The posts must be no more than 8 feet apart, and the guardrail must be able to withstand a force of at least 200 pounds in any direction.

Consider a new commercial roof with a 20-year warranty. Without regular commercial roof maintenance, that roof will likely last only 15 years before replacement. If the roof costs $525,000 to install, that’s an average of $35,000 per year over 15 years.

With a comprehensive commercial roof maintenance plan, however, you can likely double the life of that asset, and many manufacturers will even extend your warranty. With regular inspections and maintenance—where caulk is freshened, drains are cleared, and potential future problems are identified and addressed—you may get 30 years out of that same, well-maintained roof. At a $525,000 installation cost, that’s only $17,500 per year—a cost savings of $17,500 annually.

Extended roof life more than offsets the small annual cost of commercial roof maintenance, which may only be a few thousand dollars. Commercial roof maintenance also drives other significant benefits every year, including:

- Delaying roof replacement

- Preventing leaks

- Avoiding building damage

- Maintaining and extending warranties

- Fixing roof components vs. having to replace them

- Eliminating headaches for yourself, the building owner, and the occupants

Regardless of the age and state of your current roof, preventative maintenance can create value. In most cases, with regular inspections and care, you could still double the remaining life of your roof, as well as gain the advantages above.

2. Ensure Roof Hatch Safety

Roof hatches, sometimes referred to as roof scuttles, provide a convenient means to access the roof. However, they also create serious fall hazards. OSHA standard 1910.28 requires guardrails to protect all exposed sides of roof hatches.

Roof Hatch guardrails have the same requirements as the general guardrails above. In addition, the hatch protection guardrail system must have a self-closing gate that swings away from the hatch. Finally, when the hatch itself is not actively in use, it should always remain closed.

3. Maintain Fall Protection for Skylights

Skylights are great for letting in natural light, but falling through skylights is a real risk. OSHA’s skylight fall protection requirements are also covered in section 1910.28, treating skylights the same as a roof hatch and requiring protection.

Skylight protection can be achieved with a fixed guardrail, but the most common solution is to install a well-secured skylight screen. Skylight screens must be able to withstand a load of 200 pounds and prevent glass breakage, which could injure the people below.

In some situations, a skylight might be painted over, hidden or otherwise obscured. Pay special attention as this can create a significant hazard if it’s not protected.

4. Add Warning Lines Near Roof Edges

Whenever work is being performed on the roof near an edge, OSHA 1926.502 requires warning lines to mark the area within six feet of the roof edge. Workers are not allowed to go beyond that line unless necessary.

If work must be performed within that zone, conventional fall protection systems must be in place. These can include guardrails, safety nets or personal fall protection devices. Be sure that any contractors or workers always follow these rules.

5. Limit Roof Access

For both roof maintenance and safety, roof access should only be granted when necessary. First, more people accessing the roof usually means more repairs will be required. Secondly, from a safety standpoint, fewer people on the roof means less risk of an accident.

Make sure that anyone accessing your roof clearly understands the requirements for reporting damage, cleaning up after work and following safety practices. We recommend that they agree to these rules as a condition of access.

6. Keep Detailed Records

Knowing who is on the roof at any time is critical for safety. For example, if a building needs to be cleared but no one is aware that an elevator mechanic is on the roof, it could create a serious safety hazard. Always make sure that people who access the roof sign in.

Also, all commercial building owners must report severe incidents like fatalities and hospitalizations to OSHA. Those with more than ten employees or in designated higher-hazard industries may also need to maintain routine OSHA injury and illness records. If you’re not sure of what requirements apply to your facility, we can help.

7. Close and Lock Hatch Doors

Always keep roof hatches and access doors closed and locked to prevent unauthorized access. Roof hatches must not lock, however, from the roof side. This ensures that anyone accessing the roof does not get stuck on the roof.

While on the roof, personnel should close the hatch door and open it again once work is finished. Keeping the hatch door closed when not in use is important to reduce fall risks.

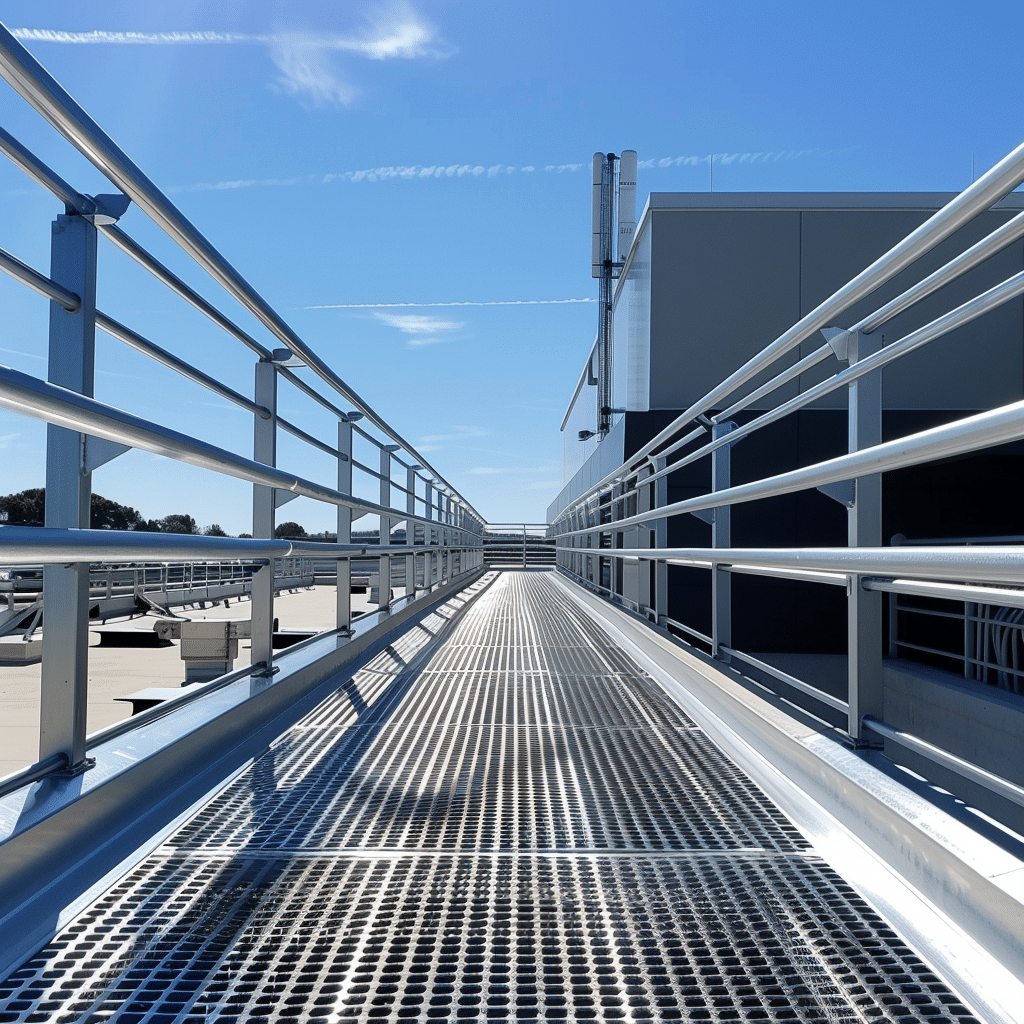

8. Add Elevated Walkways or Walk Pads

Like lines on a road, walkways and walk pads keep roof traffic where it is meant to go. This reduces accidents by keeping people in a safer zone. Elevated walkways can also be installed to route traffic away from sensitive areas such as gas lines or to increase safety around changes in elevation.

Walkways and walk pads also provide maintenance benefits. Installing these around frequently accessed mechanical equipment keeps that traffic off the membrane surface and prevents wear and tear or accidental damage.

9. Be Aware of the Weather

Weather can create major safety issues. Since a rooftop offers no sun protection, there is a higher potential for heat stress. High winds can blow objects off the roof at the risk of those below. Excessively wet, windy or icy roofs can create dangerous situations for personnel.

Be sure to only allow roof access under safe conditions. If your roof begins to leak but conditions are unsafe for access, we recommend temporary leak mitigation measures to protect property and equipment. Work with a team that has the expertise and techniques to help with this type of emergency mitigation.

10. Find a Trusted Roofing Partner

Having a trusted roofing contractor on your side can add significant value. At Roofing Corp of America, we understand commercial roof safety regulations, requirements and best practices and can help you implement the steps above.

In addition, we can provide you with simple, no-charge recordkeeping and hatch safety resources, help make sure preventative maintenance is in place and deliver priority access to repair services if needed.

Contact us to learn more about our comprehensive roof maintenance program, RoofAdvantage 360. Our experts will thoroughly assess your roof, uncovering any maintenance issues and identifying potential safety risks. We’ll deliver comprehensive recommendations taking into account the unique aspects of your building. Whether you are responsible for one facility or dozens, RoofAdvantage 360 will help you enhance safety, extend the life of your roof and provide overall peace of mind.